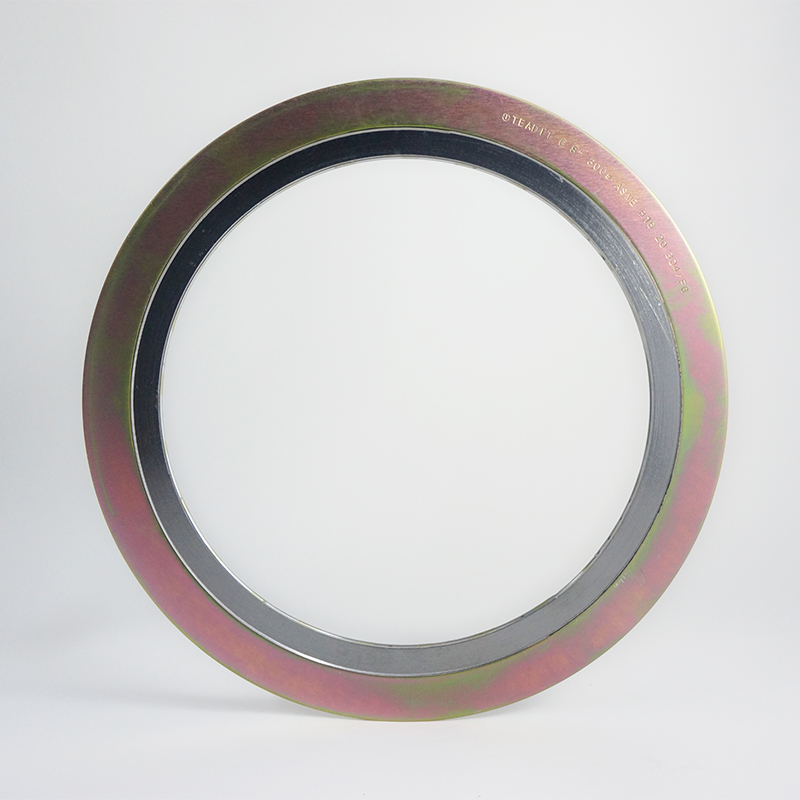

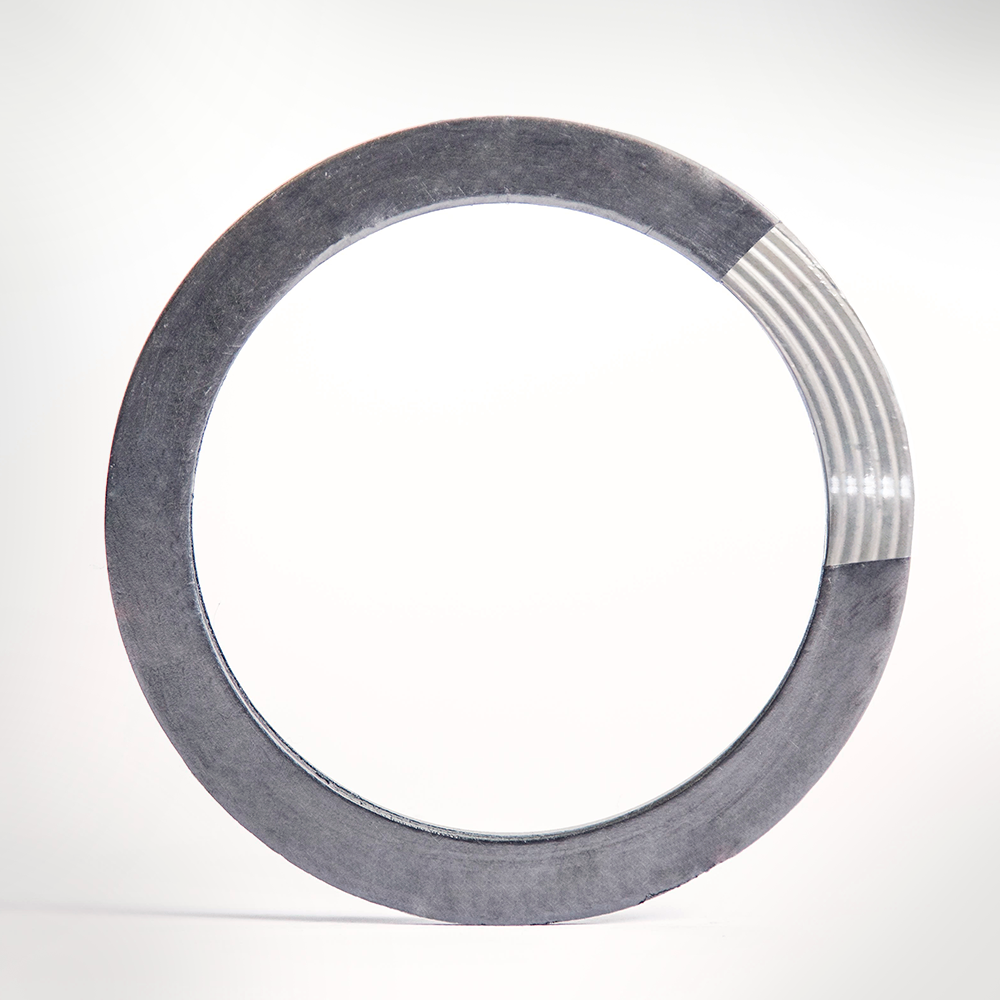

Camprofile Style 942 and 946

Excellent Results in Critical Applications

Description and Applications

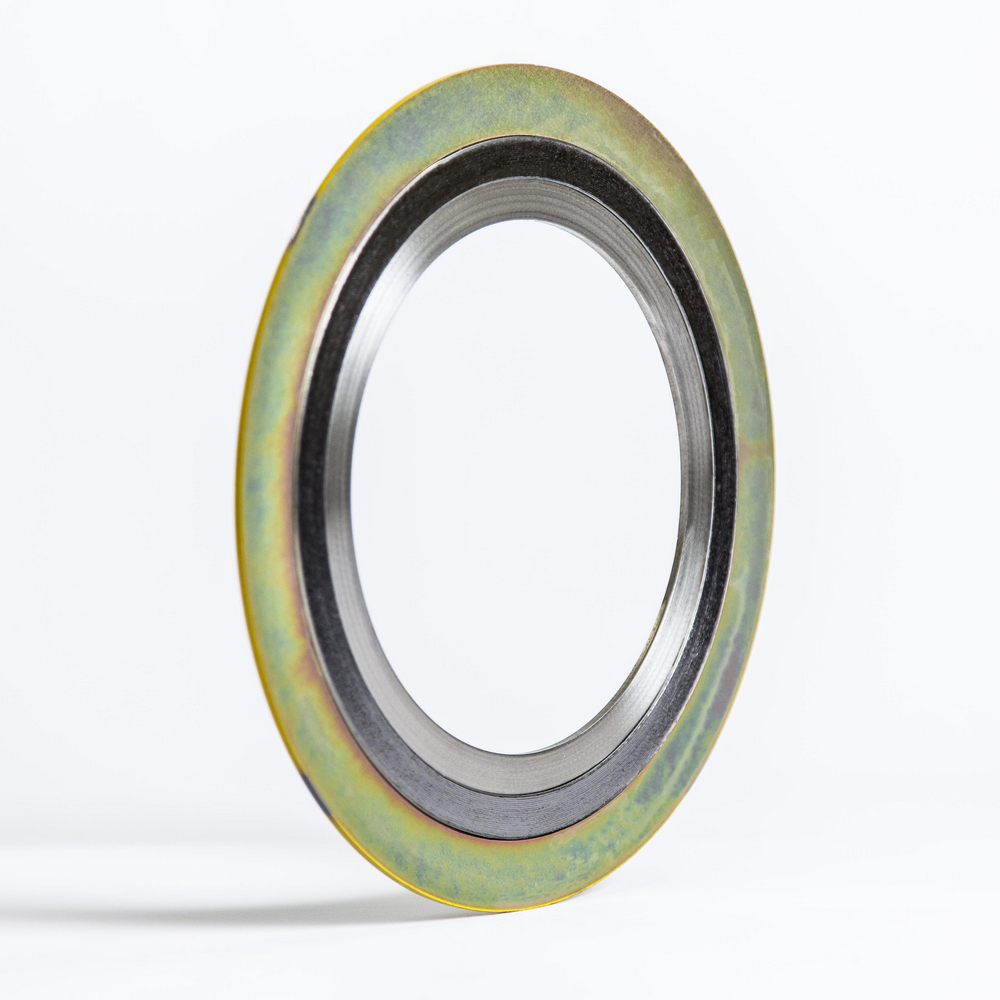

Teadit® Camprofile gaskets offer outstanding flexibility, assuring seal integrity under pressure and temperature fluctuations, flange rotation, bolt stress relaxation and creep.

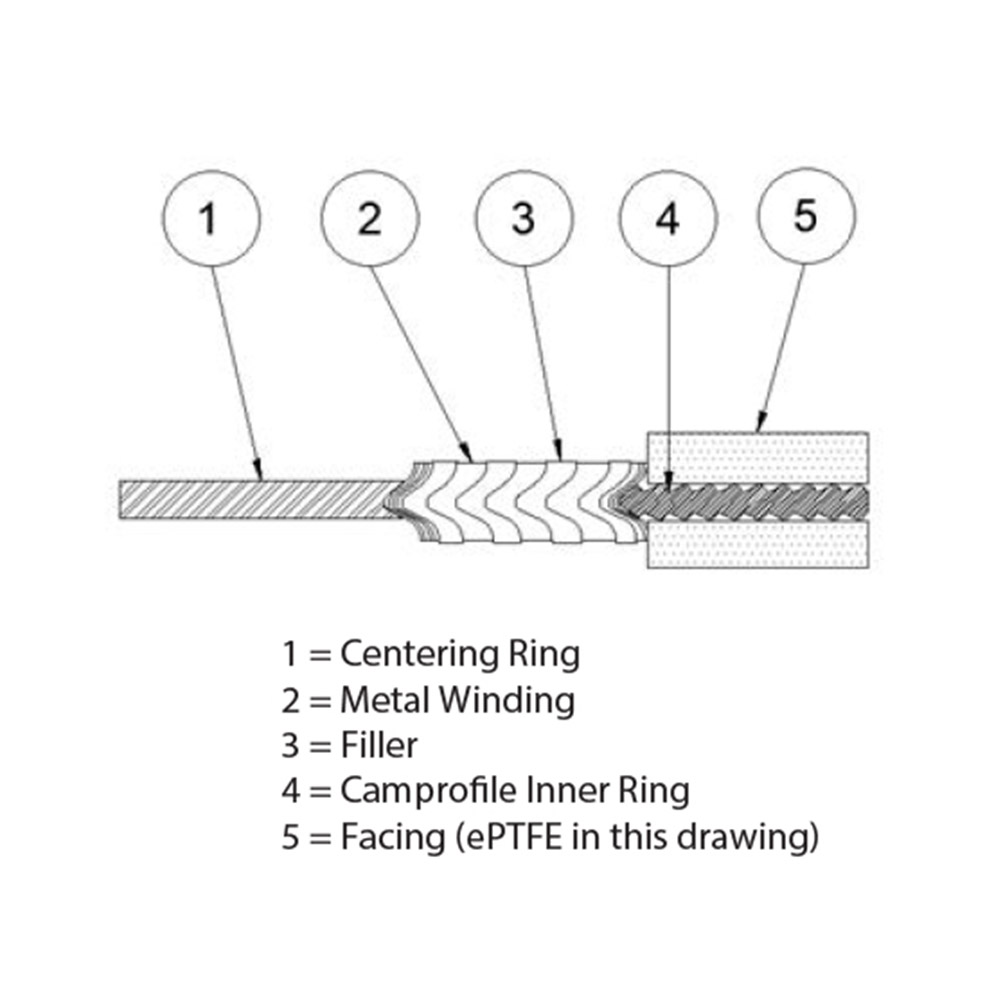

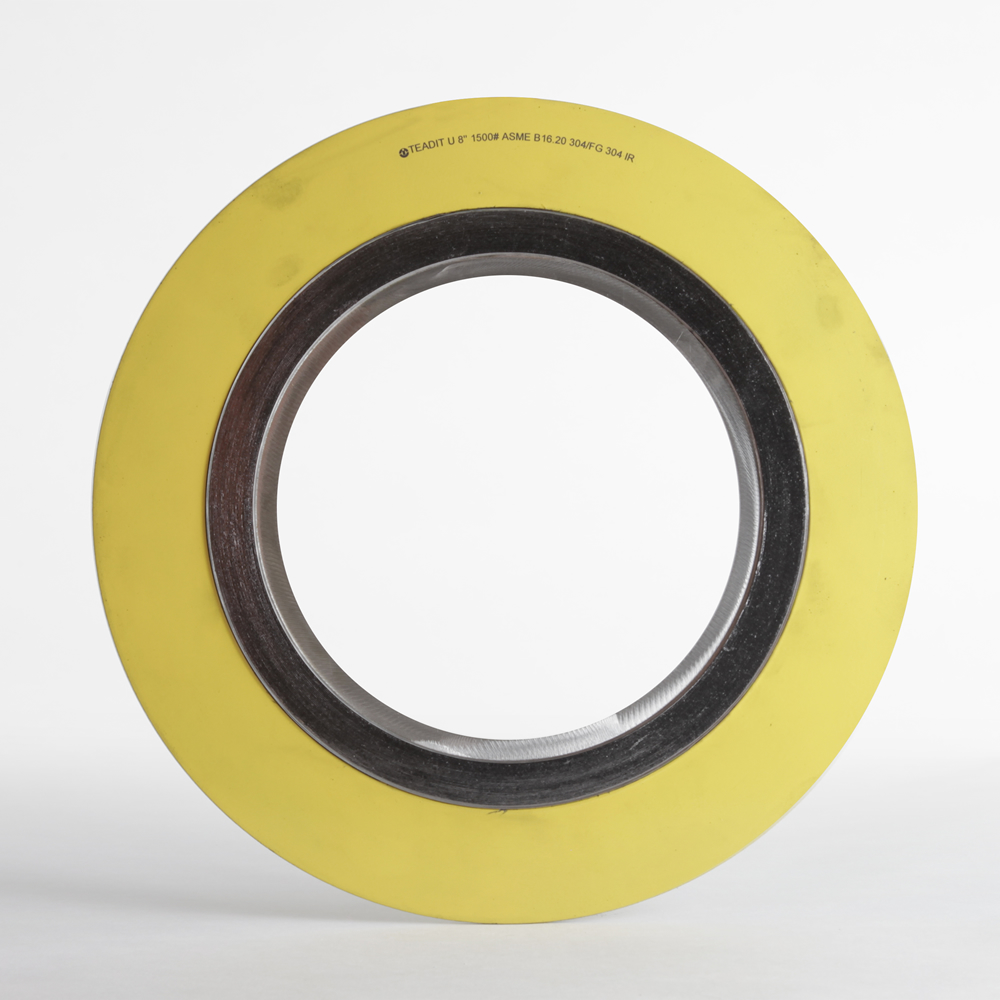

Teadit® Camprofile gaskets are used by the chemical and petrochemical industry, as well as in power stations and refineries, on both standard pipework and special applications, e.g. shell and tube heat exchangers, etc. Camprofile gaskets are constructed from a precision serrated metallic core with soft facing materials - flexible graphite or expanded PTFE - bonded to either side.

Depending on the kind of metal used, Teadit® Camprofile gaskets can be used for all media from pH 0 to 14.

Materials

The core material should be chemically and thermally compatible with the fluid to be sealed. If possible, the core metal should be the same as used to manufacture the flanges to avoid corrosion or differential Thermal Expansion.

Facing

The most widely used covering material is Flexible Graphite. For operational conditions where Flexible Graphite is not recommended Expanded PTFE is used.

The chart below shows the Temperature and Pressure limits for the cover materials.

DATA SHEETS

-

Brand

Product Name

Data sheet link