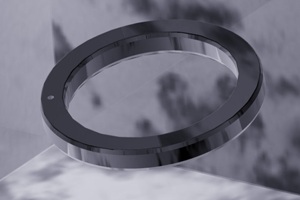

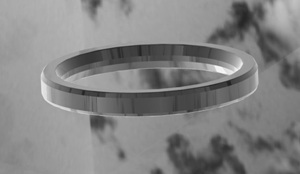

R type

R type ring Joint gaskets comprises of two types such as Oval cross section and an Octagonal cross section. These types of gaskets are used in pressures up to 10,000 PSI. The dimensions are standardized and require specially grooved flanges. Sealing occurred in Octagonal cross section with the wedge contact, Oval cross section with single line contact. The flat bottom groove design will accept both the Octagonal and Oval cross section. The sealing surfaces on the Ring Joint Gasket and Grooves must be smoothly finished to 63 micro inches and to be free of objectionable ridges, tool or chatter marks.